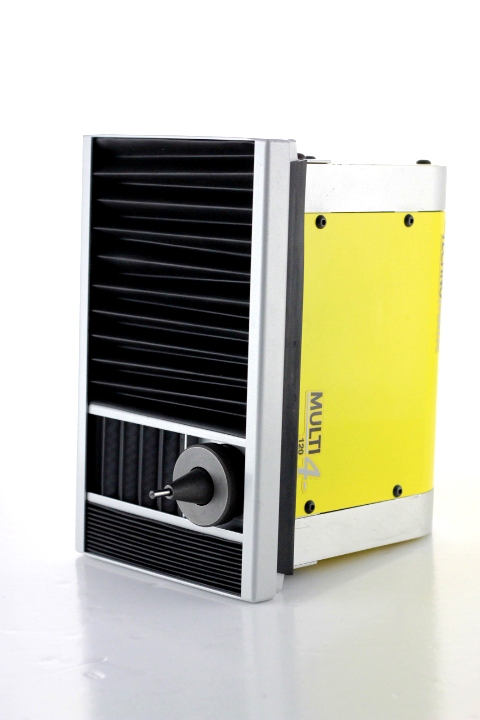

Multi4 Bench (Standard & Autosense)

The Technomark Multi4 Bench is available in both Standard and Autosense variations, providing high-speed, high-precision controlled marking ideal for alphanumeric data, symbols, logos, graphics, and data matrix (2D barcodes). It is perfect for marking small to medium-sized parts in a fixed position and is user-friendly, allowing easy setup of marking files with icon-based navigation, where most features are accessible directly from the home screen.

The Multi4 Bench offers high precision with an X/Y cross table design, ensuring consistent quality and depth over the entire window, which is particularly advantageous for data matrix codes. Its robust build features aluminium cast parts and a durable lead screw mechanism.

The device incorporates patented IDI technology for marking on uneven surfaces or components with height variations, and includes a fast vertical height adjustment with a quick-release mechanism and fine control.

The system is quiet, utilising electromagnetic technology, and comes with useful accessories such as a Rotary D axis, automatic nameplate feeder, Ethernet, cycle start pedal, nameplate holder, and 4th axis management.

The Multi4 Bench Autosense variation enhances the standard model with the ability to detect the marking face and automatically set the correct stylus offset, meeting aerospace standards for 2D barcode marking. It features a powered and programmable Z-axis, eliminating the need for manual column adjustments, and includes a 4th axis option for easy marking of cylindrical items. It is available with two marking window sizes: 50 x 60mm or 120 x 60mm.

Product Details

-

Features

- Marking Window: 2 options - 50 x 60mm, 120 x 60mm

- Fast marking - 2 characters per second (based on 3mm high text using 5 x 7 font)

- Fine Control - adjustable character height in 0.1mm increments

- Realtime stylus tracking - when re-positioning data on the screen, the stylus moves accordingly in the marking window of the head to show exact positioning

- Frequency - Ideal for both single parts and high volume production marking, with timestamp and shift code configuration

- 3rd axis board - included as standard to accommodate rotary drive or motorized Z axis (4th axis optional)

- Auto-diagnostics - built-in

-

Technical Data

-

- Marking Window: 2 options - 200mm x 60mm and 200 x 200mm

- Fast marking - 2 characters per second (based on 3mm high text using 5 x 7 font)

- Fine Control - adjustable character height in 0.1mm increments

- Realtime stylus tracking - when re-positioning data on the screen, the stylus moves accordingly in the marking window of the head to show exact positioning

- Frequency - Ideal for both single parts and high volume production marking, with timestamp and shift code configuration

- 3rd axis board - included as standard to accommodate rotary drive or motorized Z axis (4th axis optional)

- Auto-diagnostics - built-in

- Data Marking Capability

- Alphanumeric data marking with x3 fonts - 5x7, 9x13 or continuous line.with 5 levels of dot concentration adjustment

- Variable data including serial numbers, date code and time stamp, logos, datamatrix (2d barcodes). Logos can be created on your PC and integrated into your marking file, fully scalable with a range of editing functions

- Straight, angular and radial marking

- Max part height 310mm

- 90° standard stylus, 120° for datamatrix, 60° sharp point and 100mm long stylus options

- Import data from spreadsheet

- Create crossing points to navigate past a projection on the marking face, eg bolt head

- Variable force marking - 6 forces and 5 speed levels

- Depth examples - aluminium 0.4mm, steel 0.3mm

Controller

- High resolution (640 x 480) colour screen

- Create marking files on controller or on PC and transfer to controller

- RS232 connection, 3 inputs/4 outputs, optional ethernet

- 2 USB: Device port and host with fast file transfer

- Stores marking history file - editable on PC

- Energy saving - 2 configurable sleep modes

- Multi-lingual - 21 languages available

- Store up to 20,000 files or 40Mb

Dimensions & Weight

- Controller dimensions - 370 x 215 x 139 (LxWxH), 3.7kg with power cable & 4.9 including optional battery

- Bench/column dimensions - 412 x 310 x 656mm, 18kg

- Marking head dimensions -

- 200 x 60mm - 295 x 144 x 226mm, 5kg

-

-

Accessories

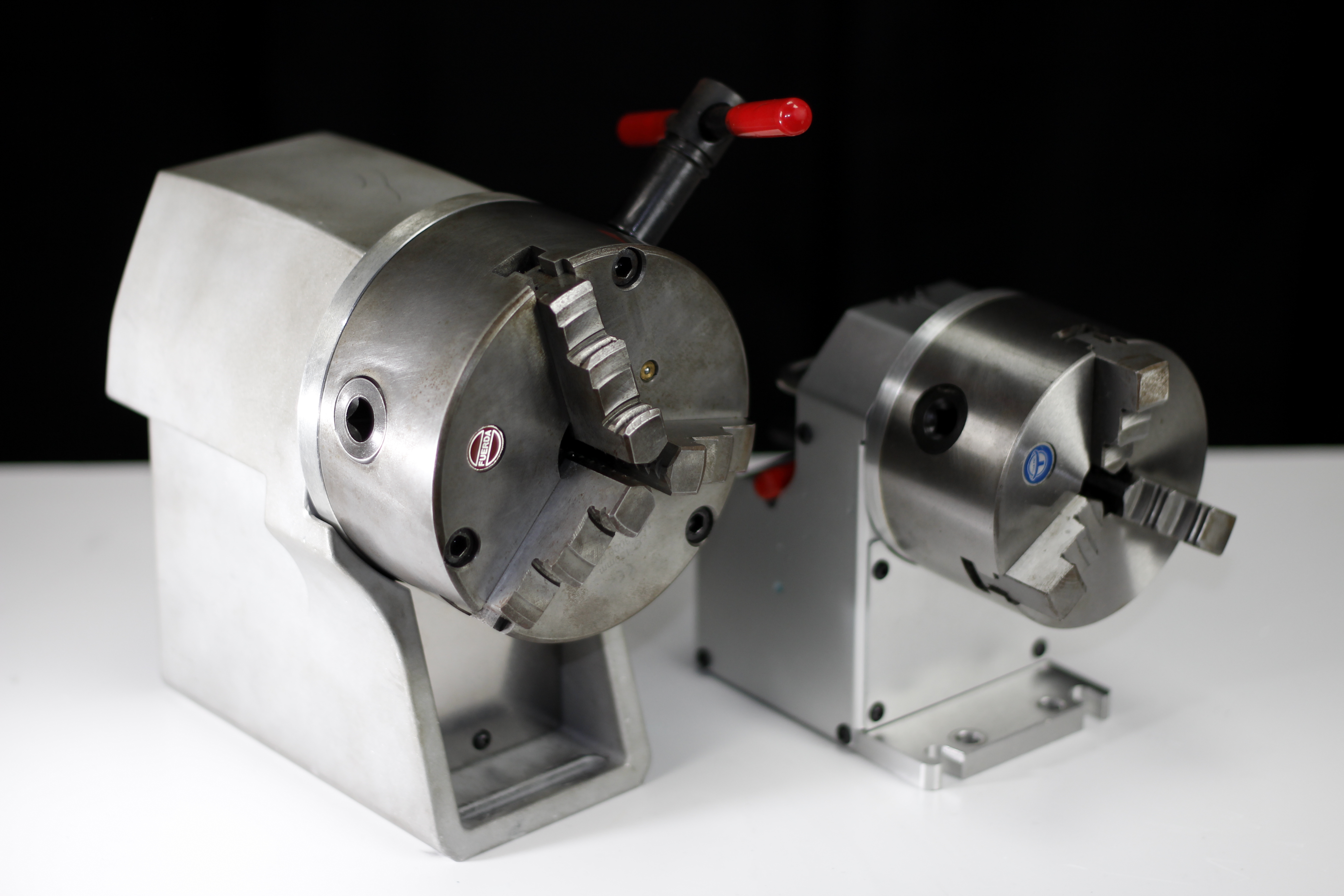

- Rotary D Axis - Standard or Heavy Duty - automatic rotation for marking cylindrical parts

- Standard marks parts up to 5kg, heavy duty up to 10kg parts

- Hold part from inside - from Ø30 to Ø90mm, heavy duty Ø40 to Ø130mm

- Hold part from outside - from Ø2 to Ø30mm, heavy duty Ø3 to Ø40mm

- Powered by controller

- Standard dimensions - 228 x 109 x 162mmm heavy duty 250 x 130 x 209

Plate Support - position and hold nameplates

- Bolts onto the Multi4 Bench

- Steel base with magnet holds plate during marking

- Working area - 178mm x 115mm

- Max plate thickness - 1.9mm

- Supplied with fixing kit

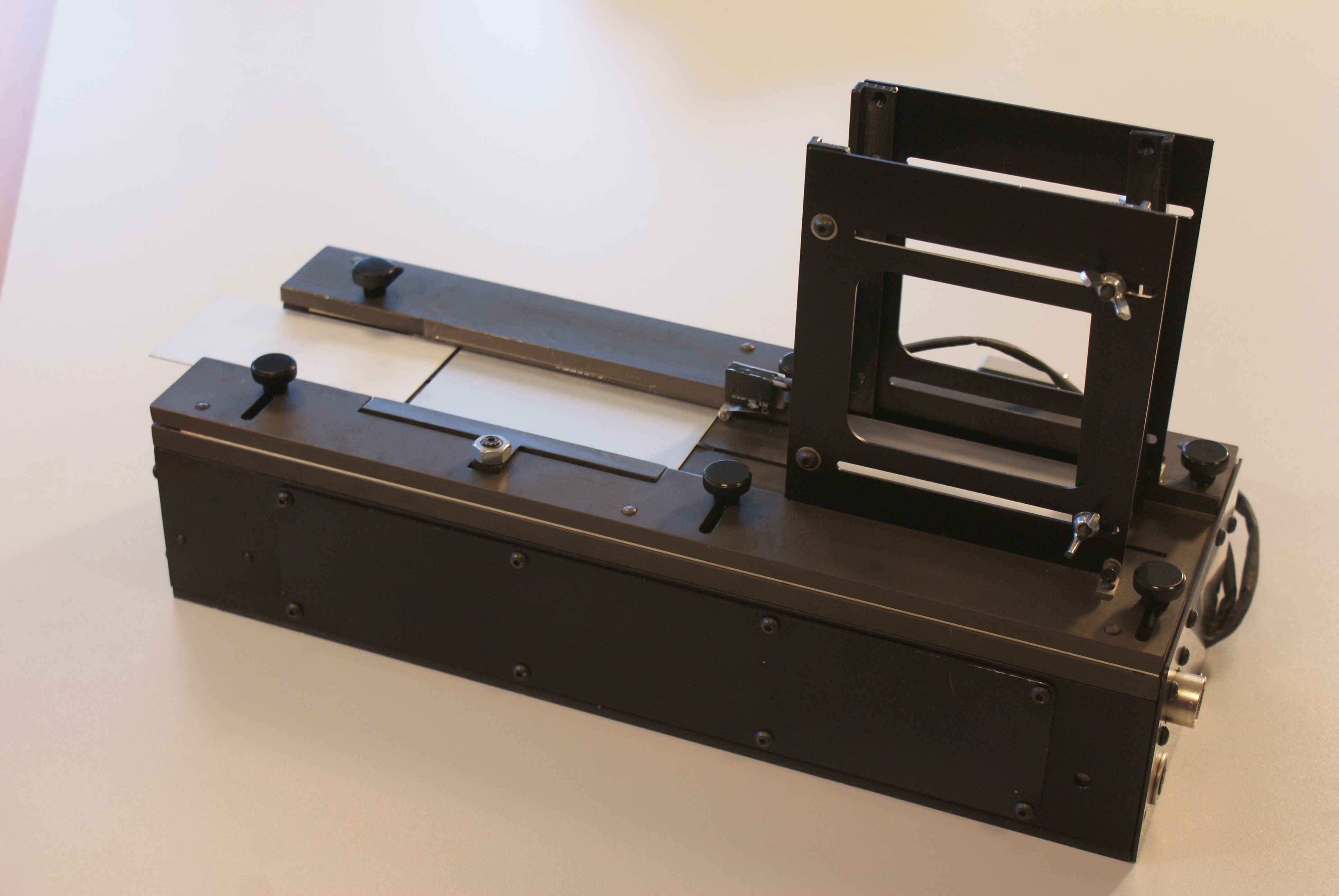

Automatic Plate Feeder - automated nameplate feed and mark

- 0.8mm +0.02 < plate thickness < 1mm +0.03mm

- Plate finish ≤0.05mm and de-burred

- Max marking area 120mm x 60mm

- Storage capacity 150 plates, 0.8mm thick

- Feeds, marks and pushes plate from marking area

Motorised Z Axis - motor driven vertical head movement on column

- Allows very fine adjustment of the stylus/part distance

- Ideal for very small to medium sized parts

- Max height of parts 310mm

- Real time display of the height on the controller screen

- Height adjustment is via a stepper motor driven lead screw

Protection Cover - protection for marking head

- Protects the marking head mechanical parts from dust and waste generated by marking some materials

- Useful when operating equipment in harsh environments

- 165 x 143 x 55mm (50 x 60 head), 0.4kg

- 235 x 143 x 55 (120 x 60 head), 0.47 kg

- 315 x 143 x 55mm (200 x 60 Head), 0.54kg

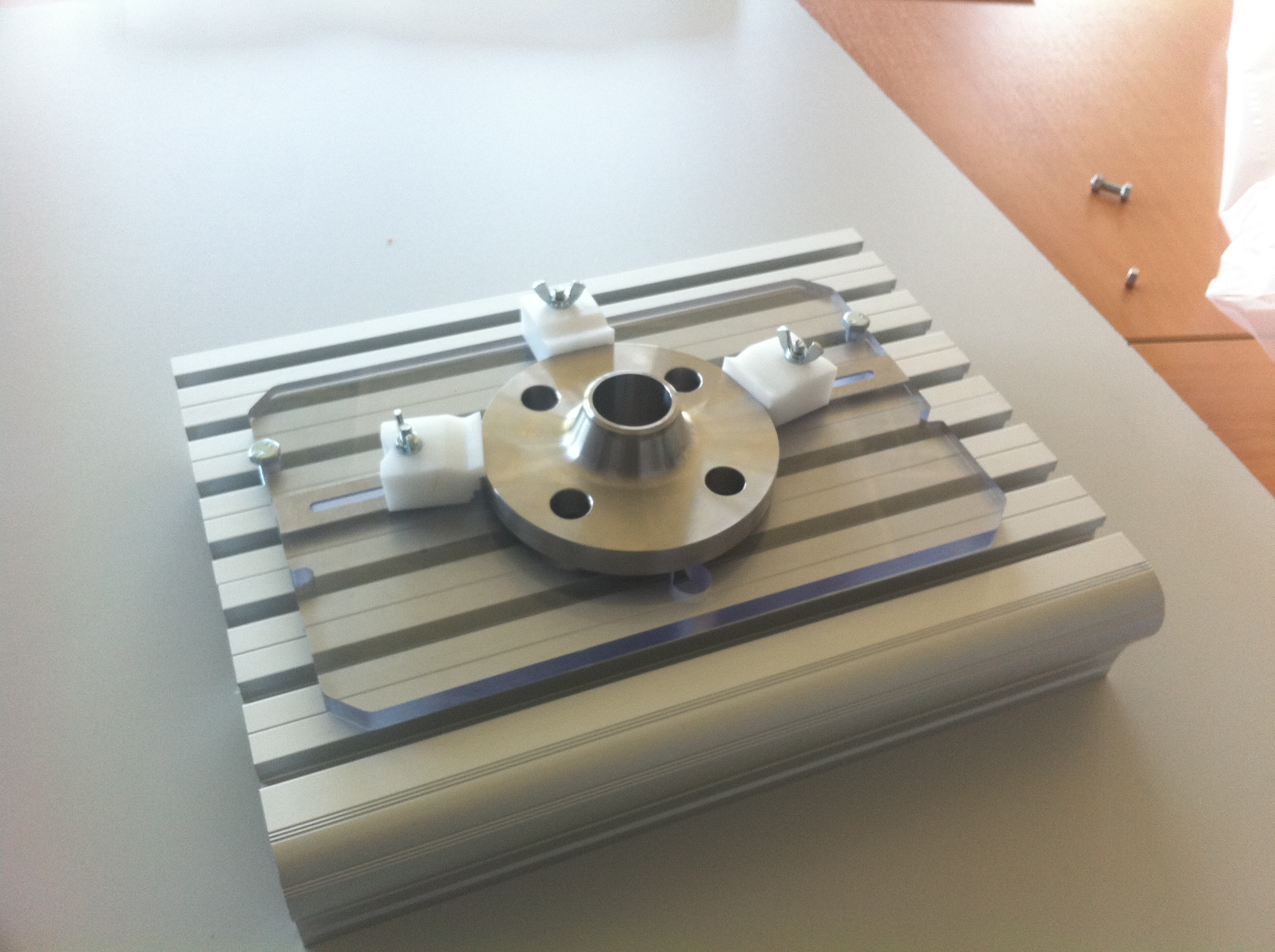

Part Support - quick positioning and holding of various shaped parts

- Holds parts without any tools required

- Easy to bolt to the Multi4 bench

- Dimensions - 278 x 163 x 52mm, 1.1kg

- Transparent polycarbonate base with Delrin holding blocks

Cycle Start Pedal & Start/Top Box

- Foot pedal to start marking cycle

- Start/Stop box to provide operator iwth more flexibility whilst marking

Maintenance Kit

- Contains 1 complete stylus assembly including stylus and spring

1 stylus, 2 springs, 1 lubricant spray and 1 USB stick

- Rotary D Axis - Standard or Heavy Duty - automatic rotation for marking cylindrical parts