The versatility and low cost of electrochemical marking technology make it the ideal technology for applying high quality marks for traceability or identification of a wide range of different metal components whatever their size, shape, thickness or hardness.

What is Electrochemical Marking?

Electrochemical marking, also known as electrochemical etching, is a process that uses an electrical current to etch markings onto metal surfaces. This method involves applying an electrolyte solution to the metal surface and then using an electrode to create a low-voltage current. The interaction between the electrolyte and the electric current causes a controlled reaction that etches the desired pattern onto the metal. The result is a clear, permanent mark that withstands harsh environments and wear.

The Versatility of Electrochemical Marking

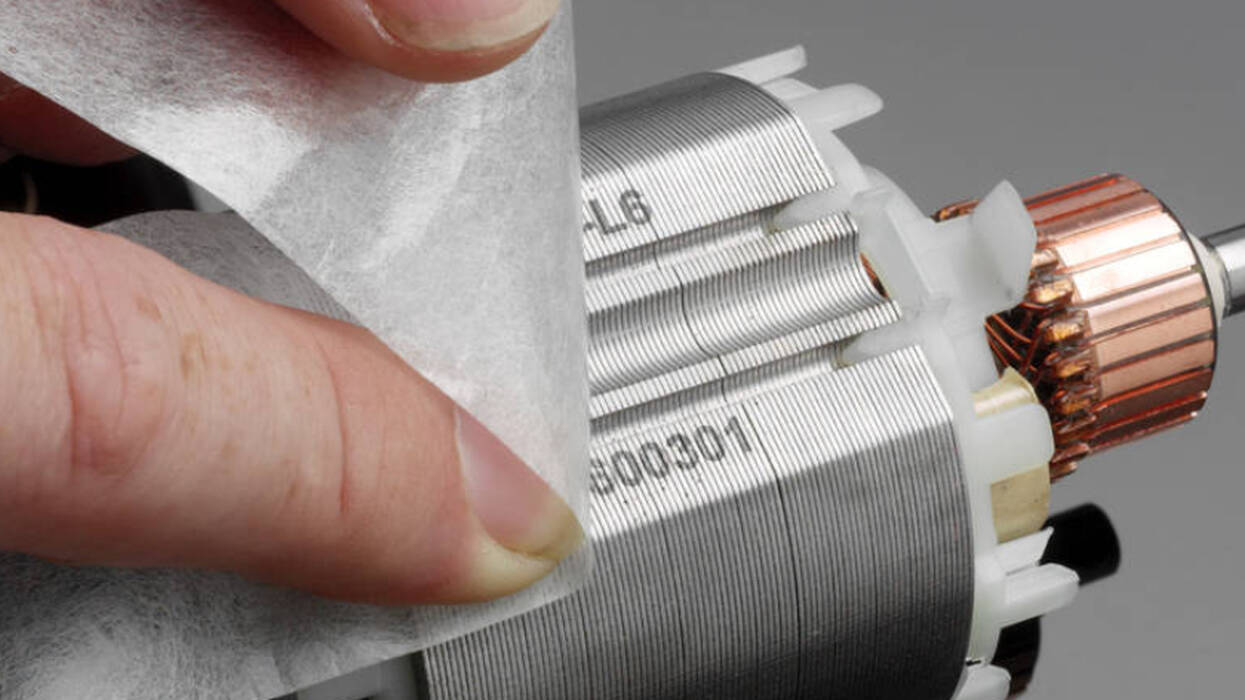

Our Metaletch electrochemical marking systems, proudly manufactured in the UK, deliver stress-free high contrast permanent marks. The marking process is incredibly fast, with most marks completed in just 1-4 seconds. Metaletch systems can mark any conductive metal surface, including stainless steel, carbon steel, mild steel, titanium, Inconel, and more, as well as create below-surface etched marks on metals like aluminum and brass. Another benefit of electrochemical marking includes its ability to mark thin wall sections that would otherwise be distorted by the heat of laser marking or the impact of dot peen.

Affordability without Compromise

Compared to laser engraving and other high-tech marking systems, electrochemical marking requires a relatively low initial investment. The equipment needed for Metaletch, including the marking machine, stencils, and electrolytes, is cost-effective. This affordability makes it accessible to small businesses and startups that might have limited budgets.

The operational cost of an electrochemical marking system is impressively low. The consumables, such as electrolytes and stencils, are inexpensive and long-lasting. Additionally, the process consumes minimal electricity, further reducing ongoing expenses. The low maintenance requirements of the Metaletch equipment also contribute to its cost-efficiency.

Electrochemical Marking & Industrial Applications

Electrochemical marking has become an essential process across various industries, including aerospace, automotive, nuclear, tooling, food processing, and medical sectors. As specialists in aerospace part marking, we have ensured that our Metaletch products meet numerous industry standards, providing detailed guidance for aerospace component marking applications. Our stencil software is aerospace compliant, accommodating a wide range of data formats and layouts, such as datamatrix, QR codes, incremental serial numbering, date/timestamp, logos, symbols, and text on an arc.

Why Choose Metaletch?

Metaletch is not just a marking system; it is a solution designed to meet the diverse needs of modern manufacturing. Its ability to mark a wide variety of metals and surfaces, coupled with low investment and operating costs, makes it an invaluable tool for industries worldwide. Embrace the future of metal marking with Metaletch and experience the difference in quality and efficiency.

Marking Support & Knowledge

Universal Marking Systems provides comprehensive support and expertise for all our marking solutions, including the Metaletch electrochemical marking range. We assist customers at every stage, from selecting the most suitable marking system to offering ongoing support years after the purchase. Our commitment to customer satisfaction ensures that you receive the best guidance and service, ensuring that your marking needs are met efficiently and effectively. Whether you're new to electrochemical marking technology or an experienced user, we're here to help you achieve the best results with our products.

For more information contact Sara Sawdy at Universal Marking Systems Ltd:

e: info@ums.co.uk

t: +44(0) 1420 565800