Laser Marking

Laser Engraving (also known as laser marking) is an extremely efficient marking technology that provides high contrast, high quality, fast marking.

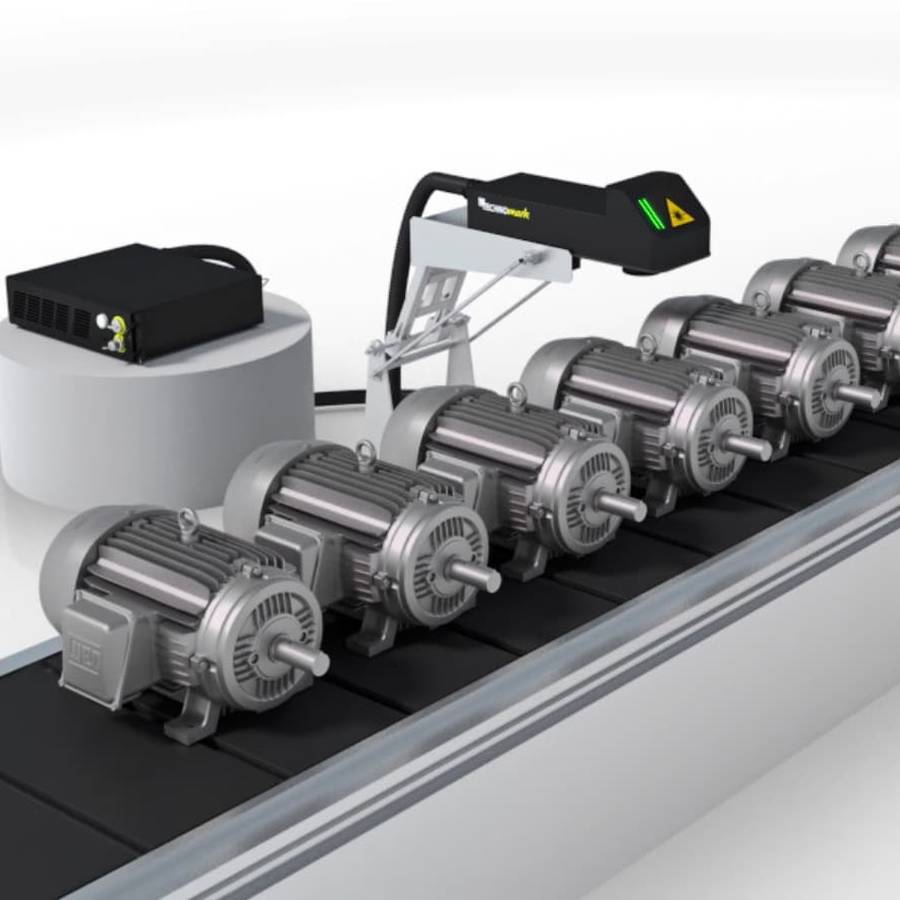

Laser engraving allows manufacturers to automate marking operations and ensures a high level of control. Laser marking is a non-contact form of marking, making work-holding simple and cost effective. Laser is extremely fast for large batch runs of the same data and delivers high quality marks. It’s good for variable marking and has a large marking area. Laser marking is ideal for workstation and production line marking as it is low maintenance. Fibre lasers are best suited for marking primarily on metals and some plastics when quality and accuracy are required. We supply and fully support the robust and reliable Technomark range, available as the Graphix Workstation system or the Graphix Inline supplied for easy integration into production lines and are developed with Industry 4.0 in mind.

Benefits include:

- High Precision and Detail: Laser marking delivers exceptional accuracy, making it perfect for intricate designs, logos, serial numbers, and barcodes. It ensures consistent quality across all parts, even in high-volume production runs.

- Permanent and Durable Marks: Laser marks are permanent, resistant to wear, corrosion, chemicals, and environmental conditions. They remain legible even when exposed to high temperatures.

- Versatility: Laser marking is versatile, capable of marking a wide range of materials, including metals like steel, cast iron, stainless steel, aluminum, brass, titanium, silver, and bronze, as well as plastics such as polycarbonate, polypropylene, ABS, and acrylic.

- Non-Contact Process: As a non-contact marking method, laser marking reduces the need for clamping, jigs, and fixtures. It also minimizes the risk of contamination and reduces the need for post-processing cleaning.

- High Speed and Efficiency: Laser systems are fast, making them ideal for high-volume production environments. They can be easily integrated into automated production lines, enhancing overall productivity.

- Cost-Effectiveness: While the initial investment in laser marking can be high, the long-term operating costs are low due to minimal maintenance, no consumables, and energy efficiency. Laser systems generally require less maintenance, reducing downtime and associated costs.

- Environmental Friendliness: Laser marking is eco-friendly as it does not require inks, chemicals, or other consumables, reducing waste and environmental impact. Periodic LEV tests are required if extraction is used.

- Flexibility: Laser marking systems can adapt to parts of various sizes, from small components to large items, without needing significant adjustments. The process is highly programmable, allowing for easy customisation of marks for different applications.

- Enhanced Traceability and Compliance: Laser marking is widely used in industries requiring strict identification and traceability standards. It can easily create 2D codes like Data Matrix and QR codes for tracking and traceability systems.

- Minimal Heat-Affected Zone (HAZ): Laser marking allows for precision control, resulting in minimal heat-affected zones. This reduces the risk of thermal distortion or damage to a wide range of materials.

To find out more, talk to one of our marking specialists by filling out the contact form or giving us a call on 01420 565 800.